Daewoo Diesel Forklifts West Valley City

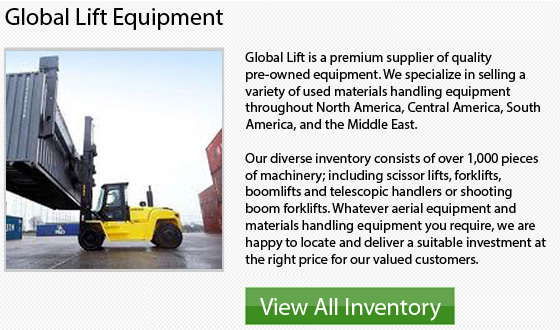

A lift truck is an essential piece of machine in the material handling business. Also called a powered industrial truck, a lift truck is utilized to carry and move supplies from one place to another. These trucks changed the warehousing and the manufacturing industries. Today they are considered to be essential for material handling and are utilized for a huge array of applications.

The forklift needs an operator who utilizes the control levers to move cargo and materials around the worksite, usually a warehouse or factory. Companies which own their own forklifts should maintain the equipment to make sure they have a long lifespan. Forklift components, like any machinery parts, are prone to wear and tear and will eventually become worn. In order to make certain the lift truck operates efficiently and safely, you should occasionally replace worn or damaged parts. Every forklift truck component is made for a specific purpose. Below is a list of some lift truck attachments and their purposes:

Forklift Fork Positioner: The forklift fork positioner is a hydraulic attachment which helps to position the forks. It can move the forks either at the same time or separately. Without the forklift fork positioner, the forklift operator has to manually adjust forklift forks for different sizes of cargo.

Side Shifter: The hydraulic side shift attachment allows the operator to laterally shift both the forklift forks and the backrest. This specific attachment makes it easier to position the cargo without having to change the truck's position.

Pole Attachments: These long metal poles are designed to carry carpet rolls. The poles work better for this purpose compared to forklift forks.

Telescopic Forklift Forks: Telescoping forks are hydraulic attachments which enable the operator to both unload and load from one side. The telescoping forks could handle two pallets of various sizes at the same time. This kind of attachment is great for handling pallets in 'double deep racking'.

- Yale Narrow Reach Forklifts West Valley City

Yale provides a range of very narrow aisle forklifts that are specifically made for maximum storage density. These very narrow aisle forklift are ideally suited for case picking and pallet handling in applicants varying from... More - Carelift Zoom Boom West Valley City

Rough terrain forklifts have been produced by CareLift Equipment, ever since the year 1962. Each day the company strives to deliver value and help all their customers reach their objectives as they know the bottom... More - Nissan Reach Forklift West Valley City

During the development of the RG Series, a lot of interviews were done by logistic managers and many truck operators. The corporation has also carried out lots of studies on ergonomics and repetitive strain injuries.... More - Manitou Outdoor Forklift West Valley City

Most businesses that are in the warehousing or shipping and receiving industries use lift trucks on a daily basis. This handy piece of industrial machine is capable of performing numerous tasks. Maintain and take care... More - Doosan IC Forklifts West Valley City

How to Utilize a Forklift Lift trucks are material handling equipment which could move loads. Most commonly, these equipment are used in certain industries to move heavy materials in a wide variety of settings such... More