Caterpillar Lift Trucks West Valley City

How to lessen the cost of damage to fork lift trucks

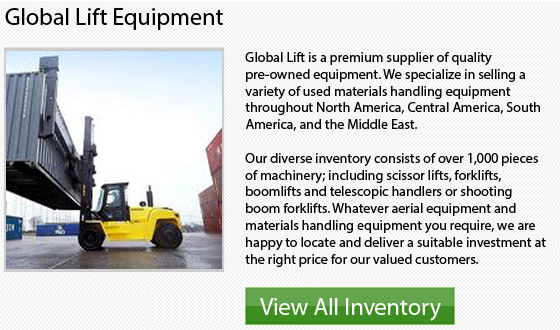

There are certain common reasons for forklift truck damage, no matter what the workplace may be. Instances of damage can be really costly. Expenses commonly relate to expenses of staff downtime and repair. Fortunately, nearly all kinds of forklift truck damage are preventable. By following these basic steps, fleet operators can ensure that repair costs and downtime are minimized or avoided.

Checking if the equipment is appropriate for the surroundings and the job is a good idea. Perform safety checks on critical systems and truck parts. Be sure that forklift operators are correctly trained and that supervision is provided. Look at the layout of the operating area/warehouse to ensure it facilitates movement. Develop a maintenance/repair plan that could guide actions when something goes wrong.

Sometimes the operator's actions are at fault, but usually the working environment itself can be the leading cause of accidents. A safe working surrounding includes having the correct equipment for the application.

The most cost-effective approach is to take a coordinated and long-term view of fleet management. The instances of damage could be reduced a lot by having the same company which supplied the trucks train the operators and perform maintenance and repairs. The company can also offer advice regarding the warehouse design.

- Yale Narrow Reach Forklifts West Valley City

Yale provides a range of very narrow aisle forklifts that are specifically made for maximum storage density. These very narrow aisle forklift are ideally suited for case picking and pallet handling in applicants varying from... More - Carelift Zoom Boom West Valley City

Rough terrain forklifts have been produced by CareLift Equipment, ever since the year 1962. Each day the company strives to deliver value and help all their customers reach their objectives as they know the bottom... More - Nissan Reach Forklift West Valley City

During the development of the RG Series, a lot of interviews were done by logistic managers and many truck operators. The corporation has also carried out lots of studies on ergonomics and repetitive strain injuries.... More - Manitou Outdoor Forklift West Valley City

Most businesses that are in the warehousing or shipping and receiving industries use lift trucks on a daily basis. This handy piece of industrial machine is capable of performing numerous tasks. Maintain and take care... More - Doosan IC Forklifts West Valley City

How to Utilize a Forklift Lift trucks are material handling equipment which could move loads. Most commonly, these equipment are used in certain industries to move heavy materials in a wide variety of settings such... More