Hyundai Dual Fuel Forklifts West Valley City

Forklifts

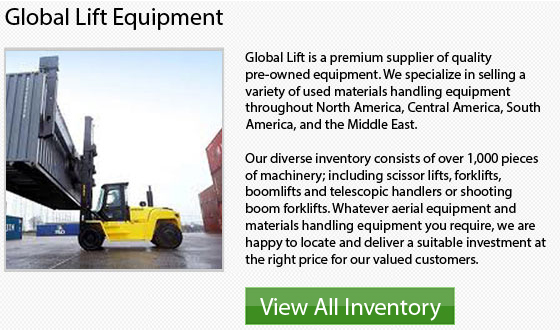

Forklifts are utilized to transport, raise and engage palletized loads in construction, material handling, manufacturing and warehousing operation. With manual-drive forklifts, the travel or load movement is either walk-behind or powered manually. Motorized drive forklifts have a motorized drive. In numerous kinds of forklifts, the forklift has a protected cab or seat for the operator. Fork trucks have features such as cabs, and backup alarms and are also motorized. Various kinds of forklifts are counterbalanced so as to prevent the vehicle from tipping over. Other models are offered with safety rails, or a rotating element such as a turntable or a hand rail.

The stroke and lift capacity are other specification that you should take into account when selecting a type of forklift. Lift capacity is defined as the maximum, supportable load or force. Stroke is defined as the difference between completely raised and fully lowered lift positions.

Several of the other vital specifications for the forklift are tire type and fuel type. The available fuel choices include: LP or liquid propane, natural gas, compressed natural gas or CNG, electricity, propane, diesel or gasoline.

There are two basic kinds of tires used for forklifts and fork trucks: pneumatic and solid. The solid or cushion tires need less maintenance compared to pneumatic tires and do not easily puncture. Air-inflated or pneumatic tires provide load cushioning and great drive traction. At the end of the day, cushion or solid tires provide less shock absorption.

Class VII forklifts are generally designed to be utilized on rough terrain. These kinds of machinery are normally used in construction, agriculture and in logging environments. Lastly, Class VIII forklifts have all burden and personnel carriers. Dual Fuel lift trucks often fit in this class.

- Yale Narrow Reach Forklifts West Valley City

Yale provides a range of very narrow aisle forklifts that are specifically made for maximum storage density. These very narrow aisle forklift are ideally suited for case picking and pallet handling in applicants varying from... More - Carelift Zoom Boom West Valley City

Rough terrain forklifts have been produced by CareLift Equipment, ever since the year 1962. Each day the company strives to deliver value and help all their customers reach their objectives as they know the bottom... More - Nissan Reach Forklift West Valley City

During the development of the RG Series, a lot of interviews were done by logistic managers and many truck operators. The corporation has also carried out lots of studies on ergonomics and repetitive strain injuries.... More - Manitou Outdoor Forklift West Valley City

Most businesses that are in the warehousing or shipping and receiving industries use lift trucks on a daily basis. This handy piece of industrial machine is capable of performing numerous tasks. Maintain and take care... More - Doosan IC Forklifts West Valley City

How to Utilize a Forklift Lift trucks are material handling equipment which could move loads. Most commonly, these equipment are used in certain industries to move heavy materials in a wide variety of settings such... More