Raymond Electric Forklift West Valley City

Forklift Battery Charging and Safe Installation

Batteries used in forklifts are pricey pieces of machines that are pretty large weighing many pounds. The task of installing and charging these batteries is something which must be planned out ahead of time in order to make certain that these methods are able to be completed safely and correctly. Maintaining a sound charging method and correct handling could really increase the battery's standard life span.

Standard Charging

It is recommended that the battery is not connected to the charger until it is at or less than 20 percent capacity. By charging the battery when it is higher than 20%, the lifespan of the battery could actually be shortened. On approximately every 5th charge cycle, the charger has to be set on the equalize or weekend setting, depending on what kind of charger you are utilizing.

The charging cycle should never be interrupted. Once the charge cycle is done, you should avoid utilizing the battery for several hours. By practicing these methods, you can help make certain that you get the maximum battery performance available.

Charger Maintenance

Make sure the charger is turned off before hooking up the battery to the charger. You then could connect the charger to the battery. This is a common error that can inadvertently cause damage to both the forklift and the charger. It is also really important that the amperage of the battery should match that of the charger.

Do not ever allow the battery to completely discharge or to deep discharge. This would shorten the battery life significantly and can even prevent the charger from being able to start. If the battery charger reads that there is no battery activity, it would not start the charge cycle. If this situation occurs, a technician should be called to be able to re-set the charger prior to charge being able to start.

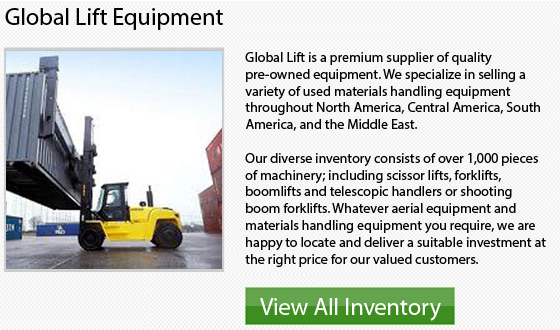

- Yale Narrow Reach Forklifts West Valley City

Yale provides a range of very narrow aisle forklifts that are specifically made for maximum storage density. These very narrow aisle forklift are ideally suited for case picking and pallet handling in applicants varying from... More - Carelift Zoom Boom West Valley City

Rough terrain forklifts have been produced by CareLift Equipment, ever since the year 1962. Each day the company strives to deliver value and help all their customers reach their objectives as they know the bottom... More - Nissan Reach Forklift West Valley City

During the development of the RG Series, a lot of interviews were done by logistic managers and many truck operators. The corporation has also carried out lots of studies on ergonomics and repetitive strain injuries.... More - Manitou Outdoor Forklift West Valley City

Most businesses that are in the warehousing or shipping and receiving industries use lift trucks on a daily basis. This handy piece of industrial machine is capable of performing numerous tasks. Maintain and take care... More - Doosan IC Forklifts West Valley City

How to Utilize a Forklift Lift trucks are material handling equipment which could move loads. Most commonly, these equipment are used in certain industries to move heavy materials in a wide variety of settings such... More