Comedil Cranes West Valley City

Tower Cranes Grow to New Heights

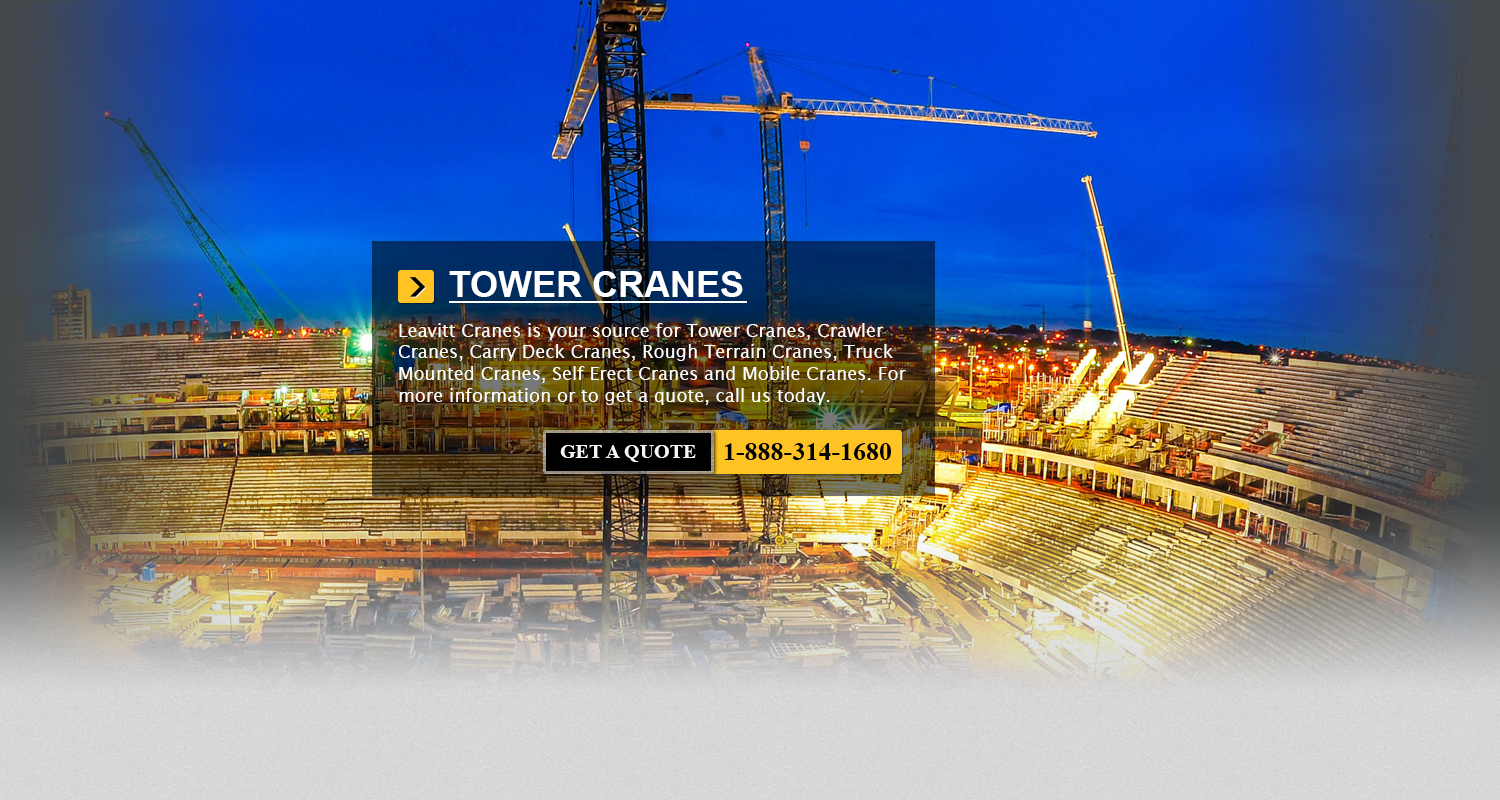

In the tower crane industry, the 1950s featured many significant milestones in tower crane design and development. There were a range of manufacturers were beginning to produce more bottom slewing cranes which had telescoping mast. These kinds of equipments dominated the construction industry for office and apartment block construction. Many of the leading tower crane manufacturers abandoned the use of cantilever jib designs. Instead, they made the switch to luffing jibs and eventually, utilizing luffing jibs became the standard method.

In Europe, there were key improvements being made in the design and development of tower cranes. Usually, construction locations were constricted areas. Having to rely upon rail systems to transport a large number of tower cranes, ended up being too difficult and expensive. A number of manufacturers were offering saddle jib cranes that had hook heights of 80 meters or 262 feet. These cranes were outfitted with self-climbing mechanisms which allowed sections of mast to be inserted into the crane so that it could grow along with the structures it was building upwards.

These particular cranes have long jibs and could cover a bigger work area. All of these developments precipitated the practice of constructing and anchoring cranes inside a building's lift shaft. Then, this is the technique that became the industry standard.

The main focus on tower crane design and development from the 1960s started on covering a higher load moment, covering a bigger job radius, faster erection strategies, climbing mechanisms and technology, and new control systems. Furthermore, focus was spent on faster erection strategies with the most significant developments being made in the drive technology department, among other things.

- Yale Narrow Reach Forklifts West Valley City

Yale provides a range of very narrow aisle forklifts that are specifically made for maximum storage density. These very narrow aisle forklift are ideally suited for case picking and pallet handling in applicants varying from... More - Carelift Zoom Boom West Valley City

Rough terrain forklifts have been produced by CareLift Equipment, ever since the year 1962. Each day the company strives to deliver value and help all their customers reach their objectives as they know the bottom... More - Nissan Reach Forklift West Valley City

During the development of the RG Series, a lot of interviews were done by logistic managers and many truck operators. The corporation has also carried out lots of studies on ergonomics and repetitive strain injuries.... More - Manitou Outdoor Forklift West Valley City

Most businesses that are in the warehousing or shipping and receiving industries use lift trucks on a daily basis. This handy piece of industrial machine is capable of performing numerous tasks. Maintain and take care... More - Doosan IC Forklifts West Valley City

How to Utilize a Forklift Lift trucks are material handling equipment which could move loads. Most commonly, these equipment are used in certain industries to move heavy materials in a wide variety of settings such... More